PRE-SELECTED COMPANIES ARE INVITED TO SUBMIT THE FINAL APPLICATION BY 3 October 2021 (5PM Brussels time)

How can drones guarantee visual inspection in a confined, metallic, humid, and complex environment?

About EDF HYDRO

EDF HYDRO, part of the EDF Group, is the largest producer of hydropower in the EU and wants to be a key player in the energy programmes of France and the core European countries where it operates.

EDF HYDRO

‘Energy is our future, save it!’

Industry Sector:

Hydroelectricity production

Digital Challenge:

How can drones guarantee visual inspection in a confined, metallic, humid, and complex environment?

Funding: Euro 100,000

EDF HYDRO and DigiFed

EDF HYDRO partners with DigiFed to address one of its key challenges on hydraulic inspection going beyond the state of the art and providing innovative solving market solutions.

EDF HYDRO is looking for a solution to tackle the challenge of short term hydroelectric group dismantling.

At EDF Hydro Alpes, 16 of our electricity groups are facing this challenge.

For example, it can take up to 8 years to estimate the status of each group.

The pumped hydroelectric energy storage (PHES) turbines can have between 1 and 5 Francis turbines on top of each other. The current inspection made by endoscopy does not allow to inspect in-between Francis turbines.

In addition, it involves dismantling the production group, resulting in operational inactivity.

In the short term, the solution should allow inspection of some parts of the turbine that EDF HYDRO have never seen before.

In the long term, the solution could help EDF HYDRO create well-structured plans for maintenance on their groups to reduce financial costs and to have the optimal efficiency in the electricity generation.

Additionally, EDF has launched a market analysis to identify complementary applications for our solution targeting other industrial sectors.

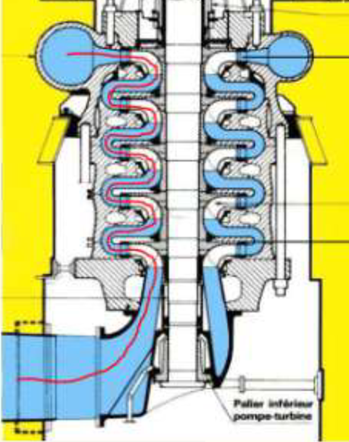

Course of the robot:

Example of a wheel:

Access to the first wheel:

Exit:

“This challenge is critical for our business operations because electricity generation is key for modern society. In the winter season, Europe just about satisfies its needs in terms of electricity generation. All the countries are relying on an interconnected electricity grid to respond to the demand. Therefore, if one or more electricity groups breakdown due to the exhaustive diagnostic testing, there are considerable negative consequences.”

EDF HYDRO understands the benefits of open innovation activities such as DigiFed Digital Challenge and is looking forward to building partnerships with innovative European companies.

Details about the Digital Challenge

Background:

EDF HYDRO, part of the EDF Group, is the largest producer of hydropower in the EU and partners with DigiFed to address one of its key challenges on hydraulic inspection going beyond the state of the art and providing innovative solving market solutions.

EFD HYDRO seeks to improve its turbine inspection procedures, reducing time and costs whilst enhancing inspection quality and predictive maintenance.

Challenge/ Problem Statement:

Currently, the inspection of the Francis turbine for hydroelectricity production pumped hydroelectric energy storage (PHES) is made by video endoscopy.

For this type of turbine (PHES), you can have between 1 to 5 Francis turbines on top of each other.

The endoscopy allows for inspection of the first and the last turbine only. It is impossible to check the turbines in between. Moreover, these wheels must also be examined to have an idea of their potential degradation and to plan efficient maintenance with minimized down-times.

The current solution is the timely dismounting and remounting of the production group. This task lasts for up to a year, which constitutes a huge loss in terms of the generation of electricity.

EDF HYDRO is looking for a solution to establish the health status of the turbine to better optimize maintenance.

For more details, photos and videos pertaining to the challenge please click on the link provided to download the Applicant Information Pack

Key Constraints:

Inspection is currently made by endoscopy and this solution is not sufficient since it requires dismantling the turbines, which makes them not operational.

EDF HYDRO has already tested and validated the frequency Wifi 2,4Ghz (with a DJI UAV) transmission between the two extremities of the turbine. The initial tests that rely on Bluetooth were not delivering promising results.

The solution should offer distance control and communication, to minimize instances of turbine damage if the robot becomes blocked inside the turbine (the solution / robot should have as little wires as possible or very short wires).

Access for a human to the top and the bottom of the turbine is possible. However, the access may require the usage of a rope or some scales, so the solution should be easily transportable by the technician (in a backpack for example).

Desired Solution:

The solution should establish the health status of the turbine to better optimize its maintenance.

The minimum requirements which are a must for the overall solution are:

Must have:

- Resistance to a metallic, humid, and complex environment.

- Resistance to shocks (50cm height absorption)

- Enough autonomy (between 30min to 60min)

- Build to pass through narrow spaces (<10cm)

- Power for ascends and descends surfaces

- – Video emission quality and pitch cam control: 12M Pixels for photo and 4K for video at a rate of 60 frames per seconds

- Pitch is needing on the camera (+90° / 90°)

- Short distance focus (about 5cm)

- Control on the intensity and why not on the direction lighting the lighting is very important with the humid metallic parts, a minimum of 10000 lumens is excepted with a diffused lighting and adjustable lighting.

- Localizing the pictures or video made inside the turbine, first time a global position will be enough (in which wheel is the robot)

- Distance control, if the robot is blocked inside the turbine, it must not damage this one.

Nice to have:

- An accurate position in the turbine

- In case the of lost transmission, the robot should be able to go to the exit of the turbine alone

- Thermal imaging

- Visual mark (graduated ruler) for dimensioning of faults

Applicant profile:

EDF HYDRO is looking to partner with innovative, mature, and qualified EU companies in wireless real time image transmission and RF propagation in challenging metal rich industrial environments (e.g. chemical plants or oil and gas).

The development of such a solution requires skills and expertise in robotics, miniaturization, and conception.

Digital Challenge Owner Support

- Challenge specific knowledge

- Access to facilities

- Resources and manpower to work with innovators to implement the technical solution

- Technical reviews and sign off meetings to ensure the development stage runs according to plan

- Benefit of joint marketing exposure

Engagements with Selected 3rd Party Beyond Digifed

We will evaluate the possibility of further work extending the scope of work of such a challenge.

We will evaluate the results exploitation terms, to guarantee business perspectives for the selected third party and EDF Hydro.

What Next:

PRE-SELECTED COMPANIES ARE INVITED TO SUBMIT THE FINAL APPLICATION BY 3 October 2021 (5PM Brussels time)

If you have any questions, please visit our FAQ dedicated page or contact: bastien.hualpa@minalogic.com or info@digifed.org

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.