Advance towards in-silico dentistry success story

Dental implants are the most reliable restoration option available for tooth loss. Despite their long potential lifespan, the clinical/aesthetic success of dental implants depends on several factors (properties of implant materials, design factors) that may result in implant failure. Dentists usually rely on their clinical experience, patient’s examination and medical imaging to determine the positional and directional information of implant fixtures and to perform drilling tasks during the procedure. This approach may cause some errors and deteriorate the implant’s quality. Objective and quantitative information would be highly desirable. Hence, the interaction between dentistry and engineering is fundamental to produce predictable devices, try them in silico and then apply the results ex vivo on patients. Soft-tissues contouring is highly important starting from the day 0 (surgical procedure) until the final restoration is placed.

Our team comes from two SME’s with complementary expertise:

- Indominus, a Spanish software vendor with a team of mathematicians and engineers with strong background in computational medicine

- Chifor Meddent, a Romanian dental clinic as an end-user, having more than 20 years of medical research experience. Our team has more than 30 publications and 3 invention patents in minimally invasive dentistry.

The challenge we addressed are current drawbacks of the implant-supported oral rehabilitations work-flow:

- aesthetic failure of 30% of implants in less than 10 years and

- mechanical failure of 10% of the dental implants

The current solutions include treatment planning software which is mainly meant for 3D drawing the implant position with a 2mm safety-limit towards the neighboring structures.

DentalFEM can improve aesthetic and mechanical outcome by at least 40%. It is also able eliminate at least 4 out of the 9 dental appointments necessary, on average, for implant-supported oral rehabilitations, thus reducing medical waste by at least 0.5 kg/patient.

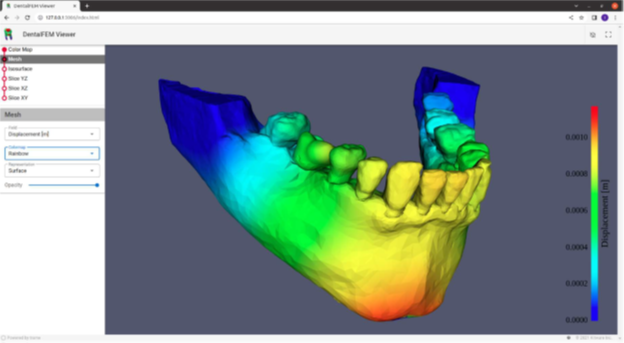

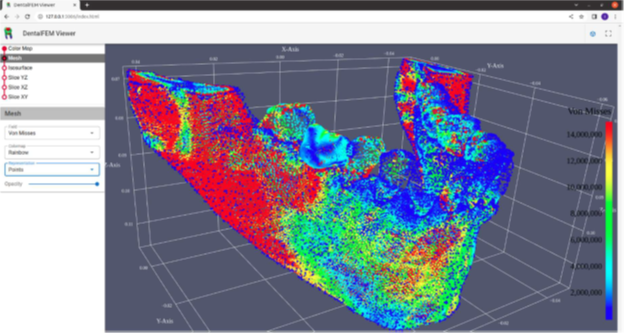

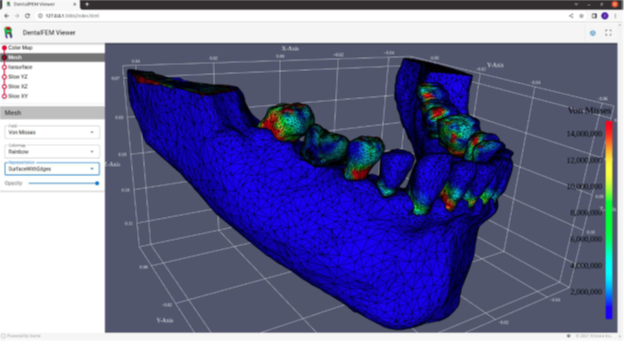

DENTALFEM is able to computationally forecast stress and deformations on every point of the patient’s oral cavity due to implant placement, and also allows to test several implant procedures, materials and designs in a patient’s digital twin based on cone-beam computer tomographies (CBCT) scans rebuilt by machine learning, thus optimising the surgery and minimising implant mechanical and aesthetic failure and its related complications.

Participating in the DigiFED project helped us gain more visibility, adhesion to DigiFED values and to benefit of very useful guidance, hence our team was invited speaker at a prestigious international conference: https://dental-conferences.magnusgroup.org/program/scientific-program/2022/mathematical-modelling-for-optimized-implantology-procedures

Published research on mechanical parameters to be considered for optimal aesthetics in dental implantology is still limited. However, the available biomedical research, mechanical engineering tests, in vitro investigations, and short-term clinical trials have, to date, reported promising mechanical, biological, and aesthetic outcomes for implant-supported oral rehabilitations.

DENTALFEM aims to be the first software tool in the market for optimised implantology procedures based on mathematical methods. A digital replica of patient’s oral cavity will be created and forces acting on implant, teeth and bone will be forecasted by means of finite elements simulations. Different implant types and acting forces can be computationally tested. Implant procedures will be no longer based only on intuition or experience of the dentist, but on quantitative and qualitative information based on physics.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.