Partner:

BME

Advanced Technology:

Design methodologies for LED based products using multi-domain LED package and luminaire digital twins

Contact:

prof. András Poppe

Email:

LEDsBeSmart

Testing, modelling and simulation methodologies of LEDs aimed at improved luminaire price/performance ratio with special emphasis on reliability and energy efficiency.

Total cost of ownership is LED based products (especially in case of large infrastructures such as public lighting / streetlighting or horticulture lighting or in case of safety critical applications like automotive lighting) is of primary importance, including reduced product cost, improved reliability and possibly improved overall energy efficiency. The approach is based on multi-domain LED digital twin based development workflow (first proposed by the Delphi4LED H2020 ECSEL project of the EU). Besides the design of thermally optimized, quick and reliable LED product the workflow provides data for designing smart control schemes aimed also at improved energy efficiency through CPS based approaches. The corner stone of this is the temperature compensated constant light output (CLO) control of the luminaires.

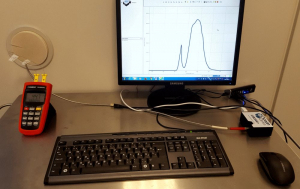

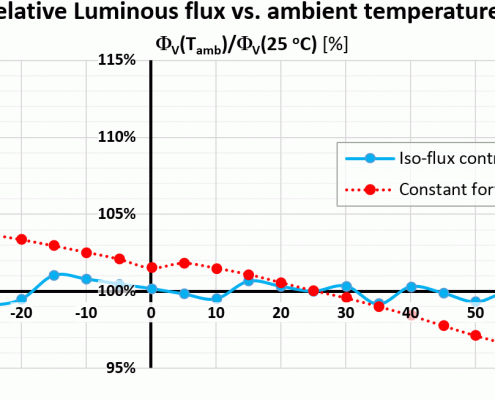

BME-DIH offers the required testing, modelling and simulation capabilities completed related consulting services, including the technical support for the implementation. The subsequent images show such an LED luminaire engineering prototype, measured at BME’s thermal and reliability testing facility.

With the comprehensive LED testing and modelling that we offer, important LED features not reported by LED vendors on their data sheets can also be considered your design.

If you are active in LED luminaire design and development and you have interest in improving your LED luminaires with the latest state-of-the-art multi-domain characterization but you lack the tools and expertise for this, do not hesitate to contact BME regarding the LEDsBeSmart technology.

Testing the temperature dependence of a smart LED luminaire’s relative luminous flux output at BME’s thermal and reliability characterization facility: the curve iso-flux control corresponds to the new temperature compensated CLO scheme implemented with a CPS platform. The annual energy saving potential of the solution under central European climatic conditions is roughly 8%.

Typical use cases

The multi-domain LED package characterization was used by Hungarian SME’s active in LED luminaire manufacturing. The overall LED digital twin based workflow is in use by a leading European based multinational lighting company and at a few French SME-s as well.

Further information can be found at

- Delphi4LED project website: www.delphi4LED.org

- EuroCPS SmartSSL industrial experiment success story

- Open access paper on multi-domain LED digital twin based product development workflow

- Open access paper on multi-domain LED modelling

Further contacts

- János Hegedüs: hegedus@eet.bme.hu

- Gusztáv Hantos: hantos@eet.bme.hu

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.