Digitalized LED application design workflow, luminaire designs optimized for thermal effects including efficiency

GE OWNER: Budapest University of Technology and Economics (Faculty of Electrical Engineering and Informatics), EET DIH, SSL group

GE Associated national project: NKFIH K_128315 project on LED modelling and reliability

GE Energy-efficient smart LED lighting community

PROPOSED SERVICE – LEDbeSmart technology for energy saving in outdoor LED lighting

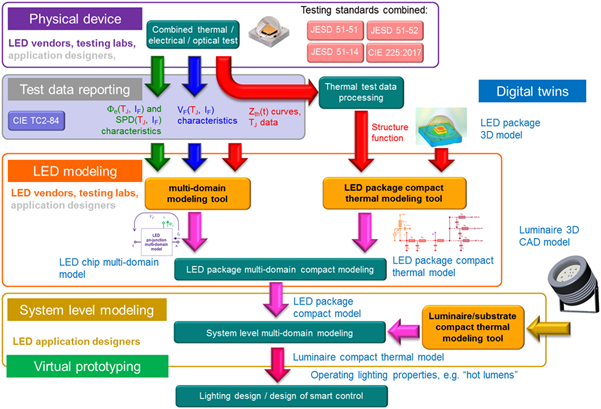

- Multi-domain characterization of LED packages aimed for the foreseen outdoor lighting application resulting in full set of isothermal IVL (current-voltage-light output) characteristics of the LEDs and their thermal resistance data

- Multi-domain compact modelling of LED packages from test data, resulting in chip level multi-domain LT Spice circuit simulation model and compact thermal model of the package structure

- Thermal modelling of the LED luminaire (enclosure / heatsink) and converting to a multi-port compact thermal model

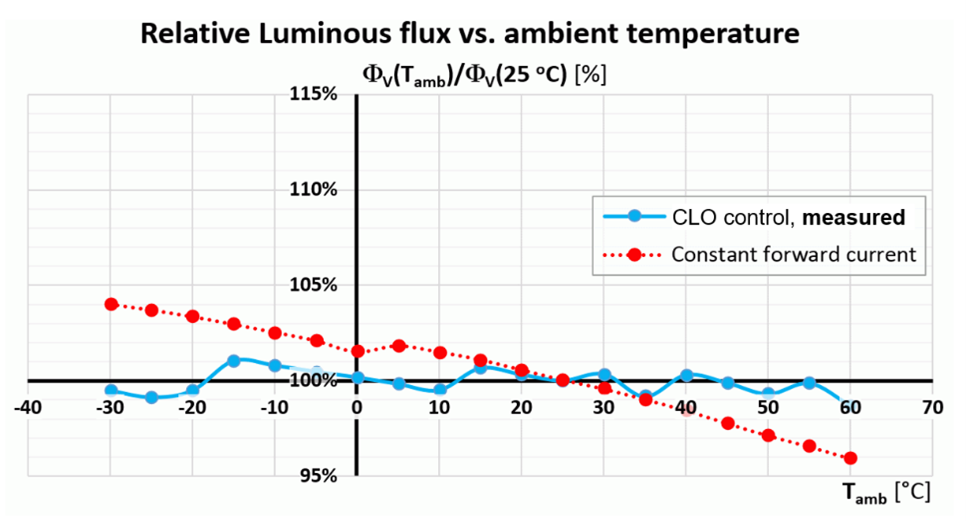

- Luminaire level LT Spice simulation of the luminaire that yields the ambient temperature – forward current relationship that assures the prescribed total luminous flux

- Consulting on the possible implementation of the above digitalised LED luminaire design workflow / assessment of the options of digitalizing the existing luminaire development workflow of the SMEs

- Consulting on the integration of the ambient temperature – forward current relationship into the dimming control of the luminaires LED drivers to assure temperature compensated constant light output

- Laboratory testing of luminaire prototypes and assessment of the energy saving potential of the implemented new control scheme

Temperature compensated constant light output control developed with the help of the Delphi4LED workflow

TECHNICAL FOCUS: Digitalized LED luminaire development workflow and implementation of a new, smart dimming scheme of outdoor luminaires

The focus of this generic experiment is to find the possible bottlenecks of the new, digitalized LED luminaire development workflow, identify the needs for improvement (such as dealing with LED ageing) and identify the most characteristic, generic elements of LED luminaire development at specialized SME’s for which a common solution should be defined, developed and offered in the near future.

The use of BME’s technology offering was demonstrated for street lighting but other application areas such is industrial indoor lighting or horticulture lighting where harsh environmental conditions may influence LED operation could also be considered and assessed.

The basic objective of the project is to establish an innovative know-how, which, with joint efforts, experience and knowledge from relevant stakeholders, will address the challenge of technologically, economically and environmentally efficient approaches, technologies and practices in optimizing LED luminaire design and application in outdoor or harsh environments where temperature swings are significant.

The BME GE technical programme will be constructed around three technological pillars that will be addressed by the GE community.

- Multi-domain LED package characterization:

- isothermal IVL measurements

- thermal measurement of LED packages

- Multi-domain LED package modelling for generic Spice simulators (such as LT Spice):

- chip level model

- compact thermal model of the physical package structure

- System (luminaire) level digital twinning for a digitalized design flow:

- thermal modelling of the physical structure of luminaires from MCAD designs

- use of multi-domain digital twin based luminaire virtual prototypes for design optimizations, beyond energy saving through temperature compensation

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.