MANU-RECOM

MANU-RECOM – Make data-based recommendations in the manufacturing site

| Type | Open Call No. | Funds granted |

| Single AE | OC 1 | €53,375 |

Challenge

Decisions, like the production process adaptation after a quality problem, in the manufacturing process are often based on experience. That works well once you have the expert, but as there is an increasing lack of experts in most domains, this way of working represents a growing risk for manufacturing businesses. Furthermore, production processes are getting more and more complex and the difficulty to understand them fully is getting harder for a human.

With the ongoing digitalization of industry, a new way of process steering is emerging: data-based decision making. However, comparatively few manufacturing sites are using their available data for even preliminary analytics.

Solutions provided

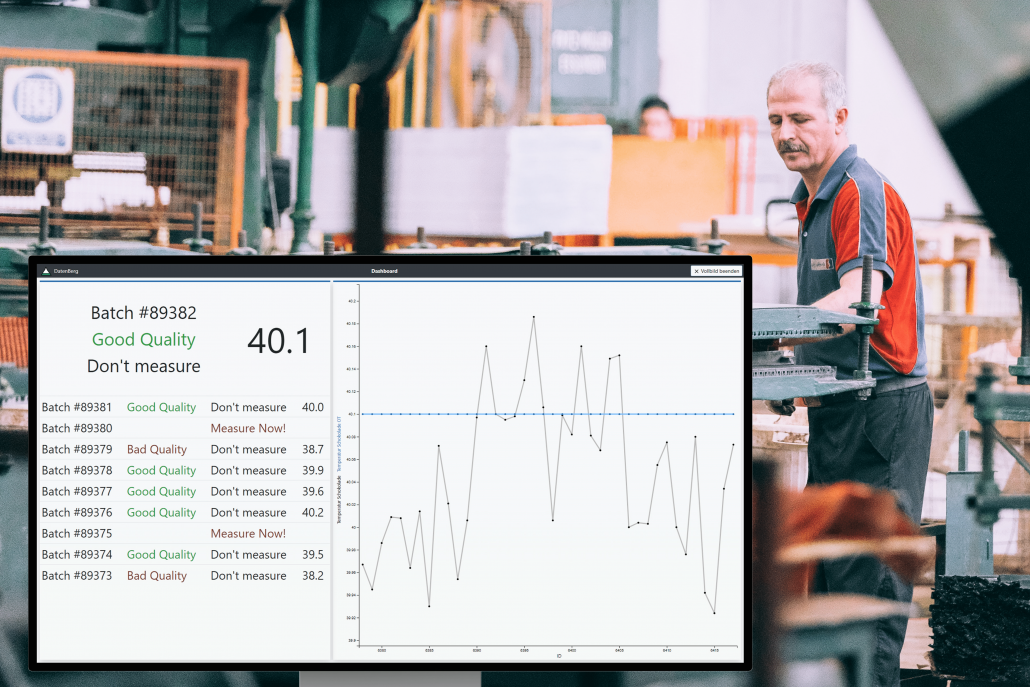

DatenBerg is offering a solution for that. With its proprietary platform smartPLAZA, manufacturing companies can consolidate data, monitor processes, analyse data and apply artificial intelligence. All that without the need of writing a single line of code or the need to have studied data science.

The software has been developed over the last three years and is deployed in production in different domains like rubber processing, textile or additive manufacturing. From a data point of view – all these production processes look similar. Therefore, the platform can be applied in each and every manufacturing process.

With Manu-Recom several very important features like automated prediction pipeline management, a powerful dashboard creator and a REST-API have been developed and tested with industry partners.

Consortium strength

DatenBerg: Existing industrial knowledge and proprietary IP are key strengths to DatenBerg

Digital Catapult: Technical expertise to optimize the smartPLAZA platform and consultation on the topic of reliable and trustworthy artificial intelligence

Business development

With the technology developed during MANU-RECOM, DatenBerg will be able to bring digital transformation to more manufacturing midcaps – easier, faster and more scalable than before. The added value of the platform increased by making the self-service analytics more powerful, this can be demonstrated with two real-world examples:

- A process intelligence manager can train and deploy prediction pipelines by themselves in less than half an hour

- Quality managers can create and deploy dashboards in less than fifteen minutes

Companies involved

The all-in-one solution for the digital transformation of manufacturing midcaps.

| Website | Company size | Country | Industry sector |

| www.datenberg.eu | Micro | Germany United Kingdom | Industry 4.0 |

Supported by

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.