SICMEQ

Software Integration to Combine Manufacturing Efficiency and Quality in Additive Manufacturing.

| Type | Open Call No. | Funds granted |

| Twin AE | OC 2 | €110,000 |

Challenge

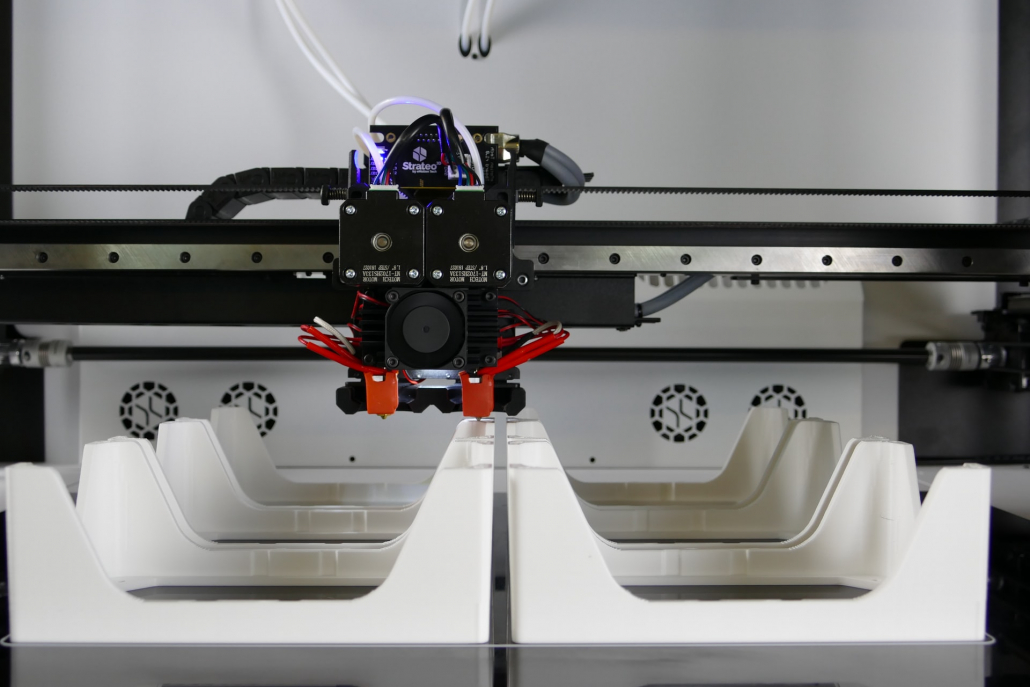

The increasing contribution of additive manufacturing to high-tech manufacturing environments (e.g. aerospace, automotive industry etc.) to deliver highly complex components raises the challenge in the form of guaranteed manufacturing quality. There is a lack of experience in terms of quality drivers for the big scale processes. Creating the required know-how takes time and effort to guarantee delivery of components with very complex geometry and very efficient use of resources at a predefined quality standard.

Solutions provided

SICMEQ relies on IoT solutions to create full transparency in production by collecting, visualizing and analysing production data. It supervises productions, plans operations and measures productivity using Authentise Manufacturing Execution System (AMES). The platform is being expanded to extend its usability to analyses of product quality using nebumind’s ‘digital product twins’ for product quality monitoring. The integrated solution enables the tracing of product quality defects to their origin and improves speedy understanding of quality drivers. It also enables online monitoring of manufacturing quality, hence identifying rework needs up to 10 times faster and reducing production rejects by up to 90%.

Consortium strength

SICMEQ integrates nebumind’s software and its quality analyses tools into the Authentise MES software. The merger of the two extremely innovative assets is to create an integrated solution for ensuring an adequate level of manufacturing quality. SICMEQ also enables integration of the proposed solution at the large manufacturing site for the demonstration of a stable manufacturing process with a considerable reduction of defects/rejects.

Business development

Starting with the pilot in the aerospace industry, SICMEQ commercializes its solution through offer of software licences. Industrialisation leverages the joint commercial potential based on the existing client pipeline.

Companies involved

nebumind supports factories with their digital transformation and offers software tools to make product quality visible, analyzable and controllable. nebumind takes production to a new level of excellence. nebumind makes data accessible, readable, valuable.

| Website | Company size | Country | Industry sector |

| www.nebumind.com | Micro (1-10) | Germany | Industry 4.0 |

Data-Driven Workflow Management

Scale your additive and high value manufacturing operations through smart use of the digital thread with the Authentise aMES. Capture insight, reduce costs and increase reliability with industry-leading connectivity and flexibility.

| Website | Company size | Country | Industry sector |

| www.authentise.com | Micro (1-10) | United Kingdom | Industry 4.0 |

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 872088.